Innovations

Research & Development

Our company has 50 technicians, and 15 of them have senior professional titles.

We have a solid ability to develop products of various materials and sizes (Square, Rectangular, Round, Nonstandard, and Beam Blanks, with a range from the smallest of 50×50mm to the largest of Dia.1500mm round tubes, 500×500mm Square tubes, 120×650 rectangular tubes).

Strong R&D abilities can meet the customer’s demand to the maximum extent. The perfect combination of experience and theories constantly improves the quality of our products. We are dedicated to shaping steel!

CCM copper moulds for special steel

Special steel has complex solidification parameters, making the precision requirements for special steel copper moulds extremely high. The taper, coating, and service life of the copper tubes are crucial for processing the corresponding special steel, and the processing threshold is also high.

CCM has successfully manufactured special steel copper moulds for Fujian Qingtuo Industrial through design and production.

CCM copper moulds for high-speed continuous casting steel

In the high-speed continuous casting production process, there are several critical technical points for the copper moulds, including vibration frequency, water distribution in the copper moulds, water-to-steel ratio, nozzle selection, spray rack, automatic control of dummy bar, and temperature limits for the intermediate ladle steel.

To meet the parameter requirements in high-speed continuous casting production, CCM has designed and produced copper moulds with dot-like and honeycomb structures.

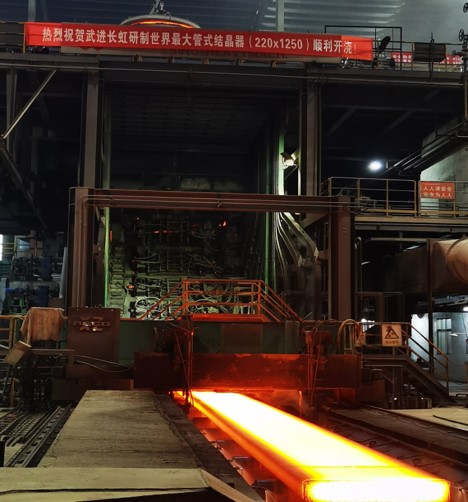

CCM extra-large size copper moulds

Large steel billets have wide applications in aerospace and new energy fields. For example, wind turbine towers play a supporting role in wind power generation units, and flanges are used to connect various tower sections. Similarly, in wind power complete equipment, flanges are also required for the installation of components such as nacelles and blades. The processing of flanges requires the forging of large steel billets. Therefore, the availability of extra-large copper moulds is crucial.

CCM exclusively supplies extra-large copper moulds (with a diameter of over 1200mm) to companies such as Jiangyin Xingcheng, Yonggang Group, Chengde Jianlong, Ma Steel, Italy’s DANIELI, and Switzerland’s CONCAST. Additionally, CCM is currently the only domestic company with the capability to produce extra-large copper moulds.