Quality Assurance

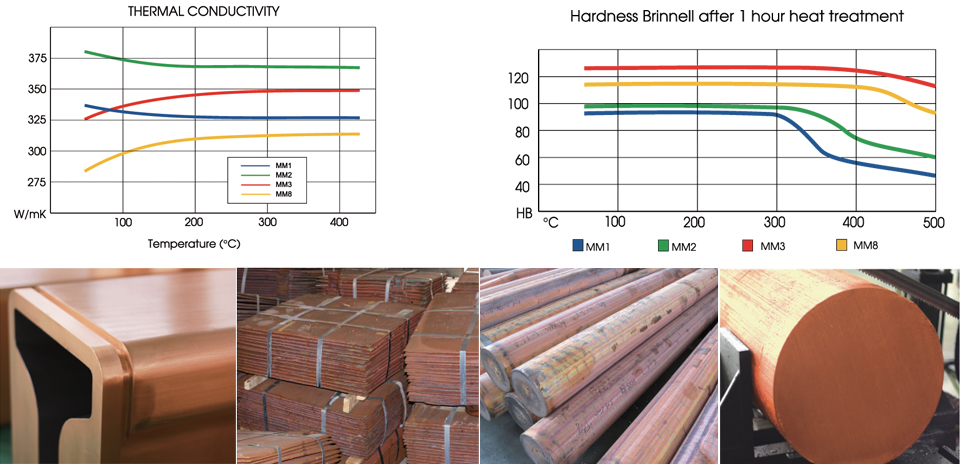

Mould Material

TP2 is a kind of material is selected by most of the steel plants.It shows excellent heat-proof and antifatigue property under high temperature and it has good processing property.

CuAg0.1 is adding 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100C, which will increase the heat stress and anti-abrasive property of copper mould tube interior surface, showing better heatresistant property than TP2.

Cu-Cr-Zr is a kind of copper allys which can be normalized by time.It has excellent mechanical property under both room temperature and hight temperature. It has hight heat conductivity, melting point, antifatigue and anti heat stress properties. Their outstanding features make it different from the previous copper alloys. It combines all good properties together. But compared with other copper alloys, Cu-CrZr is difficult to be formed with higher products costs.

| Item | Temp. | Unit | Material | ||

| CuDHP | CuAg0.1 | CuCrZr | |||

| Chemical Composition | |||||

| P0.015-0.040 | Ag0.08-0.12 | Cr0.30-1.20 | |||

| — | P0.04-0.012 | Zr0.03-0.30 | |||

| Physical Properties | |||||

| Electrical conductivity | 20 | %IACS | 83 | 95 | 80 |

| Thermal conductivity | 20 | W/(m.K) | 340 | 372 | 330 |

| Coefficient of thermal expansion | 20-300 | 10^-6/K | 17.1 | 17.1 | 17.2 |

| Recrystallisation temperature | — | ℃ | 345 | 360 | 690 |

| Modulus of elasticity | 20 | 10^3MPa | 120 | 123 | 126 |

| Melting point | — | ℃ | 1083 | 1083 | 1078 |

| Specific gravity | — | g/cm3 | 8.9 | 8.9 | 8.9 |

| Mechanical Properties | |||||

| Ultimate tensile strength | 20 | Mpa | 240-310 | 240-310 | 375-445 |

| Ultimate tensile strength | 100 | Mpa | 190-270 | 230-270 | 365-425 |

| Ultimate tensile strength | 200 | Mpa | 140-190 | 205-240 | 365-410 |

| Ultimate tensile strength | 300 | Mpa | — | 175-210 | 335-375 |

| Ultimate tensile strength | 400 | Mpa | — | 145-160 | 315-350 |

| 0.2 Yield point strength(Rp0.2) | 20 | Mpa | 190-250 | 200-225 | 280-355 |

| 0.2 Yield point strength(Rp0.2) | 100 | Mpa | 185-260 | 195-240 | 270-345 |

| 0.2 Yield point strength(Rp0.2) | 200 | Mpa | — | 180-225 | 260-330 |

| 0.2 Yield point strength(Rp0.2) | 300 | Mpa | — | 165-215 | 250-320 |

| 0.2 Yield point strength(Rp0.2) | 400 | Mpa | — | 130-145 | 240-290 |

| Elongation(A5) | 20 | % | 25_10 | 16_10 | 20-13 |

| Hardness | 20 | HB | 80-95 | 110-125 | 115-130 |

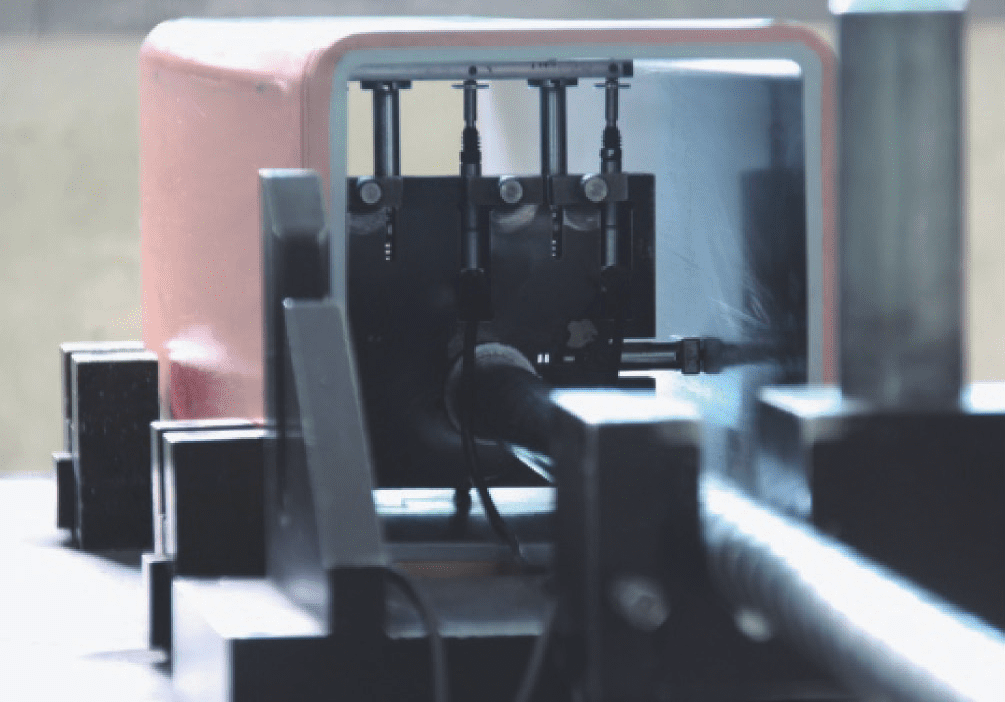

Equipment

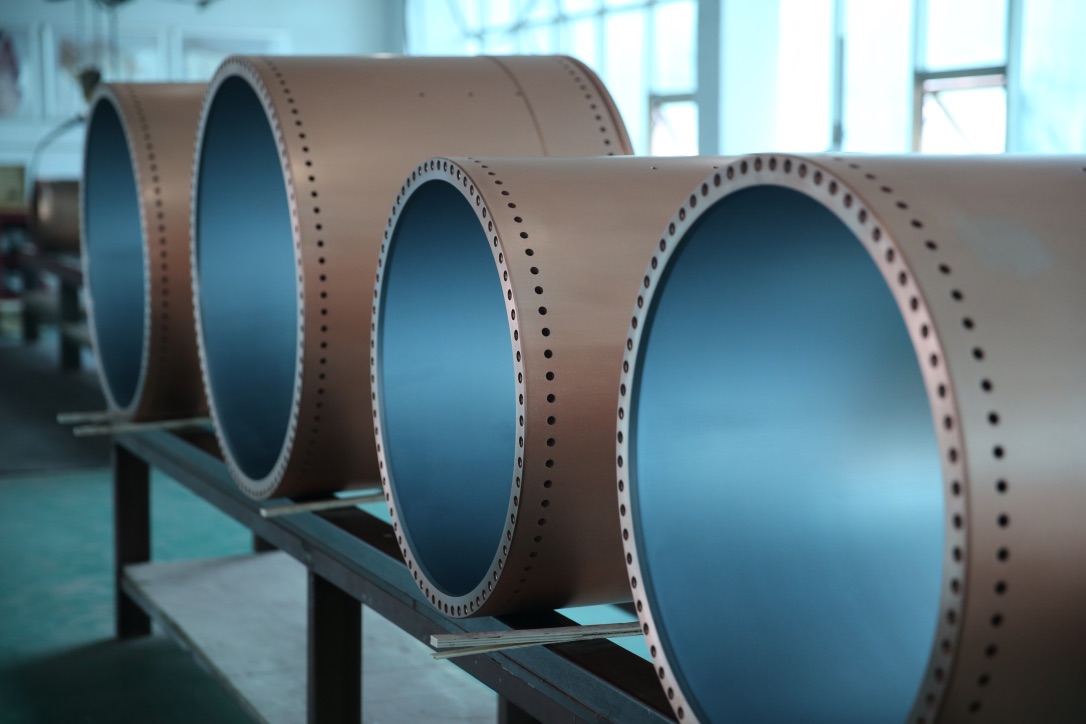

As the old saying goes, one must sharpen his tool before going to make perfect work. Our company spends heavily on the manufacturing equipment of copper mould tubes and plates. Now we have nine sets of large, medium, and small hydraulic presses, 25 nos. of CNC machine centers, and five sets of special NC processing machines, which can produce 1200 mm-diameter round tubes and 3800×1000×70mm copper plates.

Mould & Plate Coatings

We use hard chrome plating to increase the life of mould tubes. The plating thickness recommended by CCM will be controlled in the best range. As for the coating of copper mould plates, based on our years of experience, we are able to provide Cr coating, Ni-Cr coating, Ni-Fe coating, and Ni-Cr coating to meet the demand of various customers both at home and abroad.

Copper has a lower hardness which leads to lower anti-abrasive properties. Therefore, the area at the lower part of the moulds, where the stress increases drastically due to shells, will be more severely worn. To increase the lifetime of copper moulds, CCM provides uniform mould interior surface plating with suitable hardness. Most of the copper mould tubes for small-size billet casting are not used in any casting system where there is rigid casting stream support; therefore, they are very sensitive to be worn.

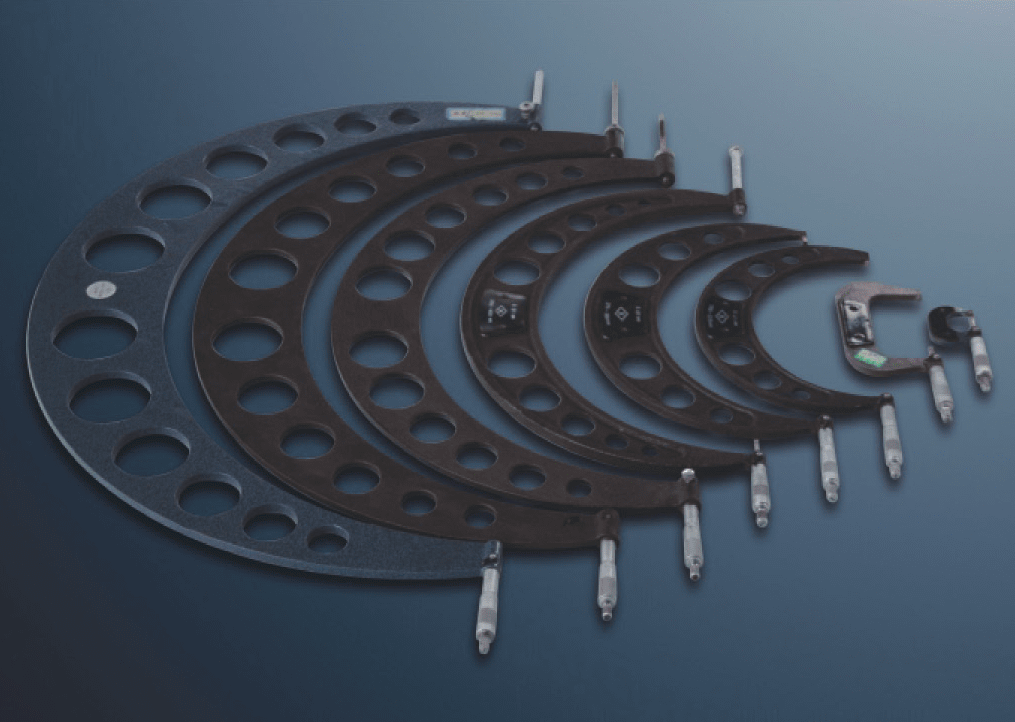

Testing Method

The target of our work is to improve our technological capacities to be in the interest of the customers. For this purpose, we have been dedicated to new product development. We established R & D department for new alloys, optimized copper taper, and better anti-wearing coating. Our physical and chemical laboratories are equipped with advanced analysis and inspection systems which provide a strong guarantee for the quality of our products.